In collaboration with audiophile artist Huib Muilwijk Made By Midas we design high-end turntables. Soon the first models will go into production!

Get turned on by Spindr!

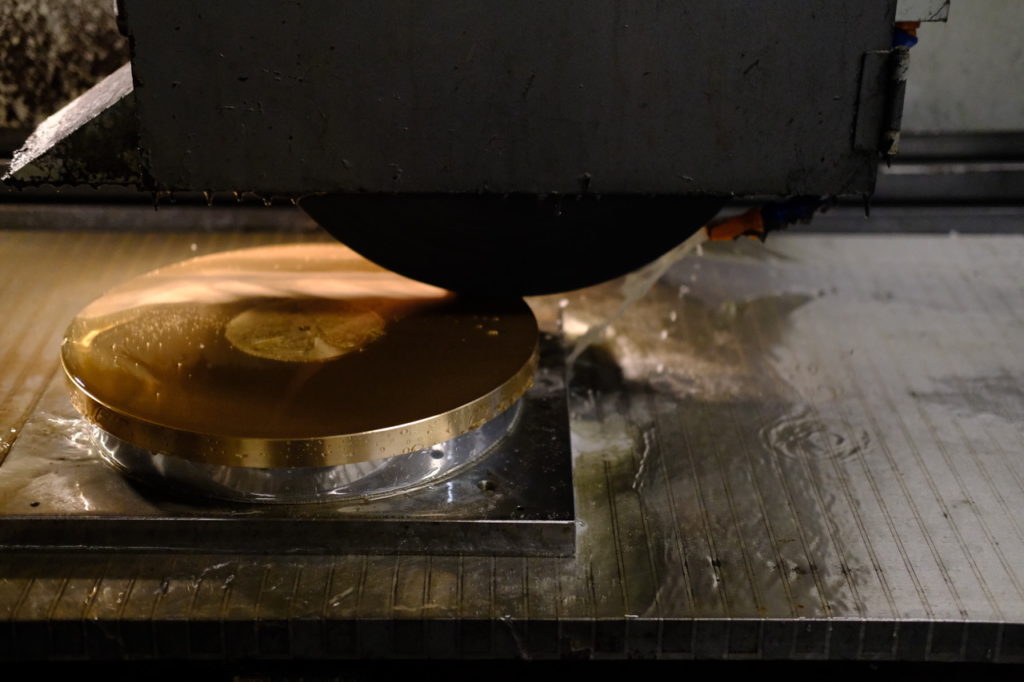

“We will not bore you with numbers on just how flat this (sub)platter is. On the aluminum die-casted by monks that we leave to mature like aged cheese and switch upside down twice a day. On the ax tolerances that can only be measured at ASML with the seventh nanometer process. The craftsmanship, or rather art, to free this platter that has been locked up inside the aluminum. Like a sculptor freeing his image from the marble.

But WOW what a great thing this is becoming, very promising for music! We quickly move forward to the following items because we still have a long way to go. “

After two years of fun and hard work, we have designed and produced a ready-to-sell Garrard 301 update. The biggest update you can find for your 301. The Garrard 301 has been technically improved on many points, while still retaining its classic look & feel. Most importantly: without losing drive, power and dynamics… the sound character that makes the 301 so popular! We carry out this update on your Garrrard 301, provided it has the original serial number, engine and mechanism.

The new deck is CNC machined from aluminum and finished in high quality laquer. We create room for an arm board and a stroboscope! This has never been done before on a Garrard 301. The new design is more rigid, so vibrations and frequencies are better absorbed.

We also create a conical mount for the bearing. This mounting method is seamless and ensures high torsional stiffness and perfect positioning of the platter. This makes the whole much more resistant to axial and radial loads.

The bearing of course is the spinning center of the record player. The bearing structure is based on the classic Garrard 301 design with bearing housing, bushings and spindle. We produced the characteristic conical shape of our bearing housing in nickel-plated cast iron. This material is extremely suitable because of its mass and vibration-absorbing properties. Hidden deep in the bearing is a vibration absorber, our player’s best kept secret up till now.

The spindle has a unique diamond coating that provides extremely little friction. As a result, there is less vibration, a constant running speed and therefore less wear on bearings and motor. A very hard, scratch-resistant layer has been applied under the coating on the contact surface with the bushings, which guarantees a long service life. The tight tolerance that we use between bearing and spindle requires a special oil. We found an extremely finely filtered oil, which is perfect!

We truly did something unique with the motor mount: it can be disconnected from the deck and mounted on the baseplate below. This way the motor is fully detached from the deck. To divert unwanted vibrations away from the needle and element, the support is heavier than the aluminum original: cast iron, finished with a nickel coating.